Verifying Alignment Of The Moving Cars For Coke Charging And Quenching

In this we will discuss about "Verifying Alignment of The Moving Cars For coke Charging And Quencing"

HOW DOES THE REAL SCENARIO LOOK LIKE?

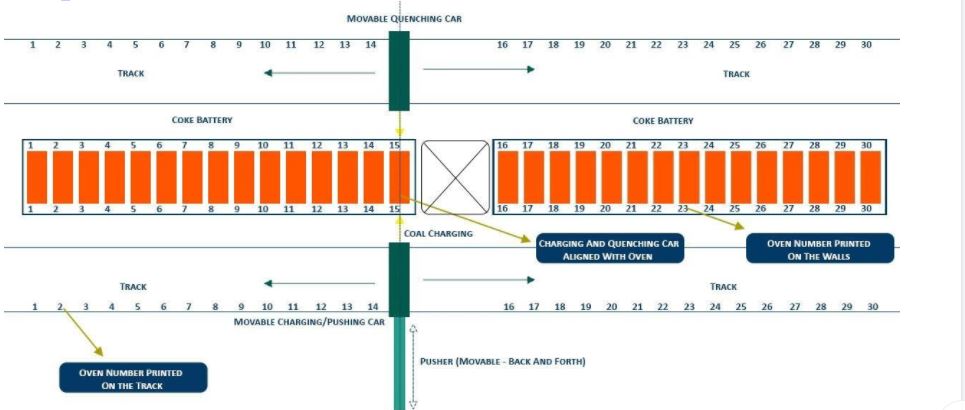

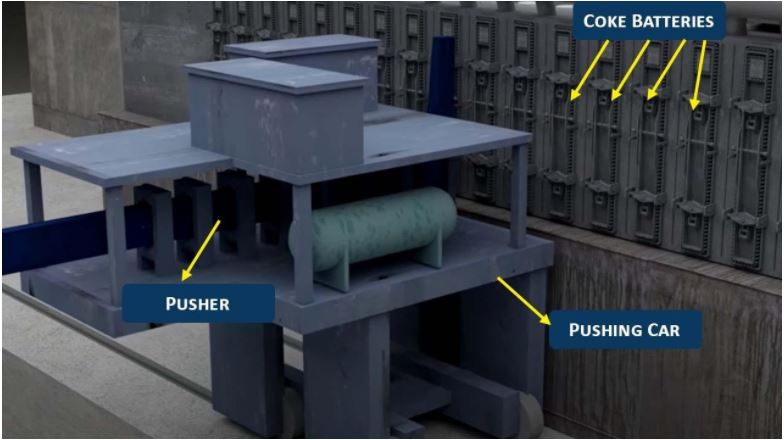

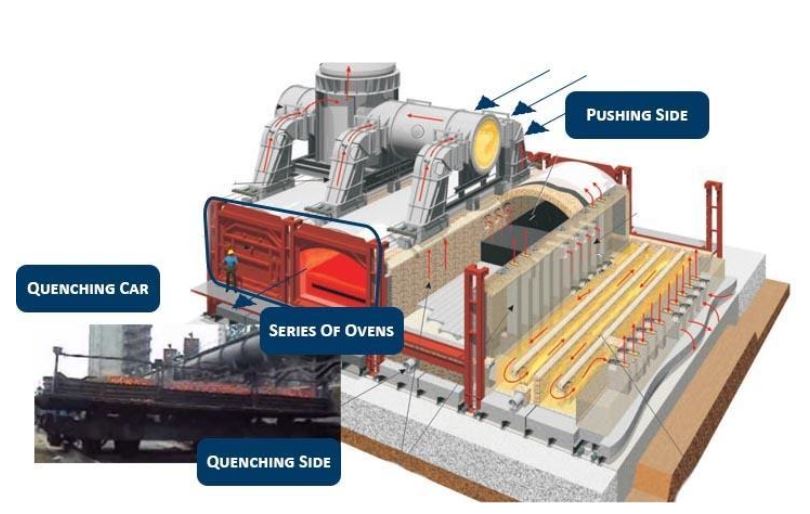

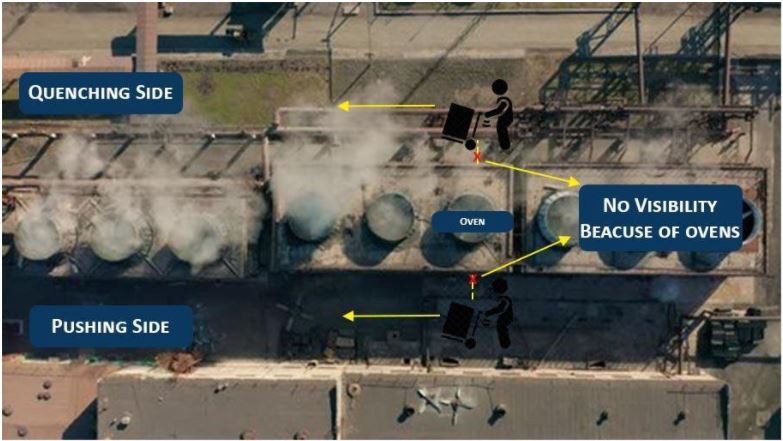

In the process of coke production, the coke is charged into the oven using a charging car. The oven is closed after feeding the coal into the oven. The walls of the oven are covered with refractories to withstand 1000 degrees of temperature. The coke is taken out of the oven by pushing it out from the oven to collect in the quenching car. In this scenario, the charging car is used for the pushing of the coke instead of a pusher. For the collection of coke, at the time of pushing the quenching and the pushing car has to be aligned with the same oven.

CLIENT REQUIREMENTS

To ensure the moving car correctly stops in alignment with the oven that is ready for pushing out the coke for quenching.

WHAT IS THE OBJECTIVE?

To prevent endangering the life of the human operators working in the process of coke production. Machine vision would not only ensure the safety of the personnel, but it will also prevent damage caused to the ovens.

CHALLENGES FACED BY CLIENTS

The oven height is 4 meters which makes it very difficult for operators to communicate and verify the alignment of the pushing and quenching car with the oven from which the coke has to be pushed out.

HOW WERE THEY CURRENTLY ADDRESSING THE PROBLEM?

The alignment check is being done by the personnel standing at both sides of the ovens. The operators check the number written on the oven and communicate through a wireless device.

WHAT WILL BE THE OUTCOME IF ALIGNMENT IS INCORRECT?

Unaligned ovens and cars are dangerous to the operator’s life while pushing out the coke. Hot burning coke can fall over the operator if he is standing in front of the oven from which the coke has to be pushed out. This will also damage the oven doors. With the help of automation, there is no requirement for human intervention in such a dangerous environment and can avoid the breakdown of oven doors.

HOW QUALITAS TECHNOLOGIES IS DEVELOPING A SOLUTION?

Qualitas Technologies has developed a solution for the alignment and communicating the signal through PLC to execute the pushing process. An AI-based vision system is a key element of the solution. Qualitas Technologies decided to deploy a vision system in the problem area. Cameras would be installed on both sides of the coke batteries, facing towards the oven, to read its number. When reading of both ends would be the same, our vision system would communicate the signal to the PLC to initiate the pushing operation.

For this solution, an OCR module will be used to read the numbers printed on the oven walls.

CONCLUSION

The problem of our client can be solved by using a single machine vision system with an OCR module. Matching the number from both sides will ensure that pushing and quenching cars are parked in front of the same oven. A vision system will read the number and ensure that it is matching before the pushing operation.

For More Visit: Vision Automation and Robotic Solution | Automated Vision Inspection | Proof Of Concept Development

Comments

Post a Comment